FIELD PROVEN RESULTS

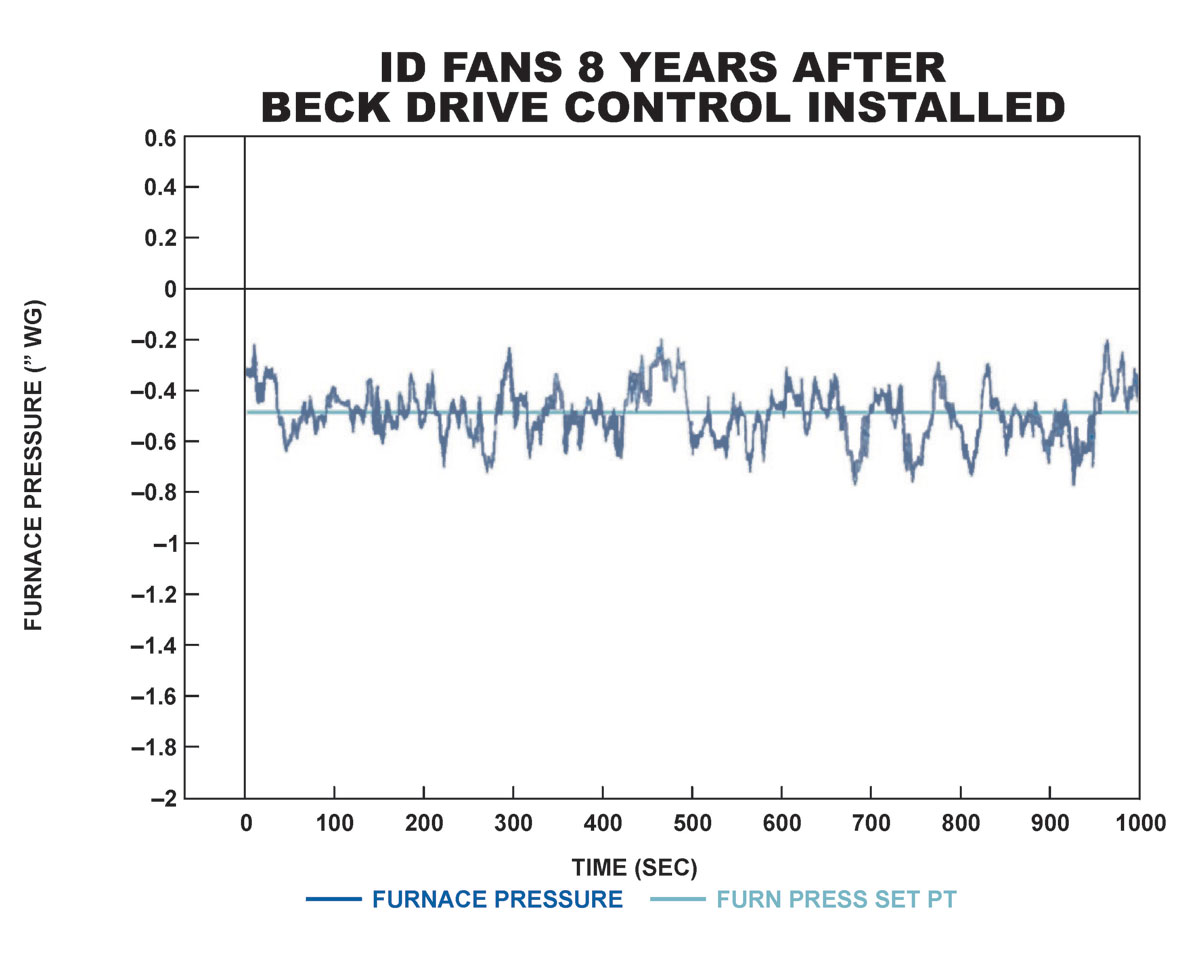

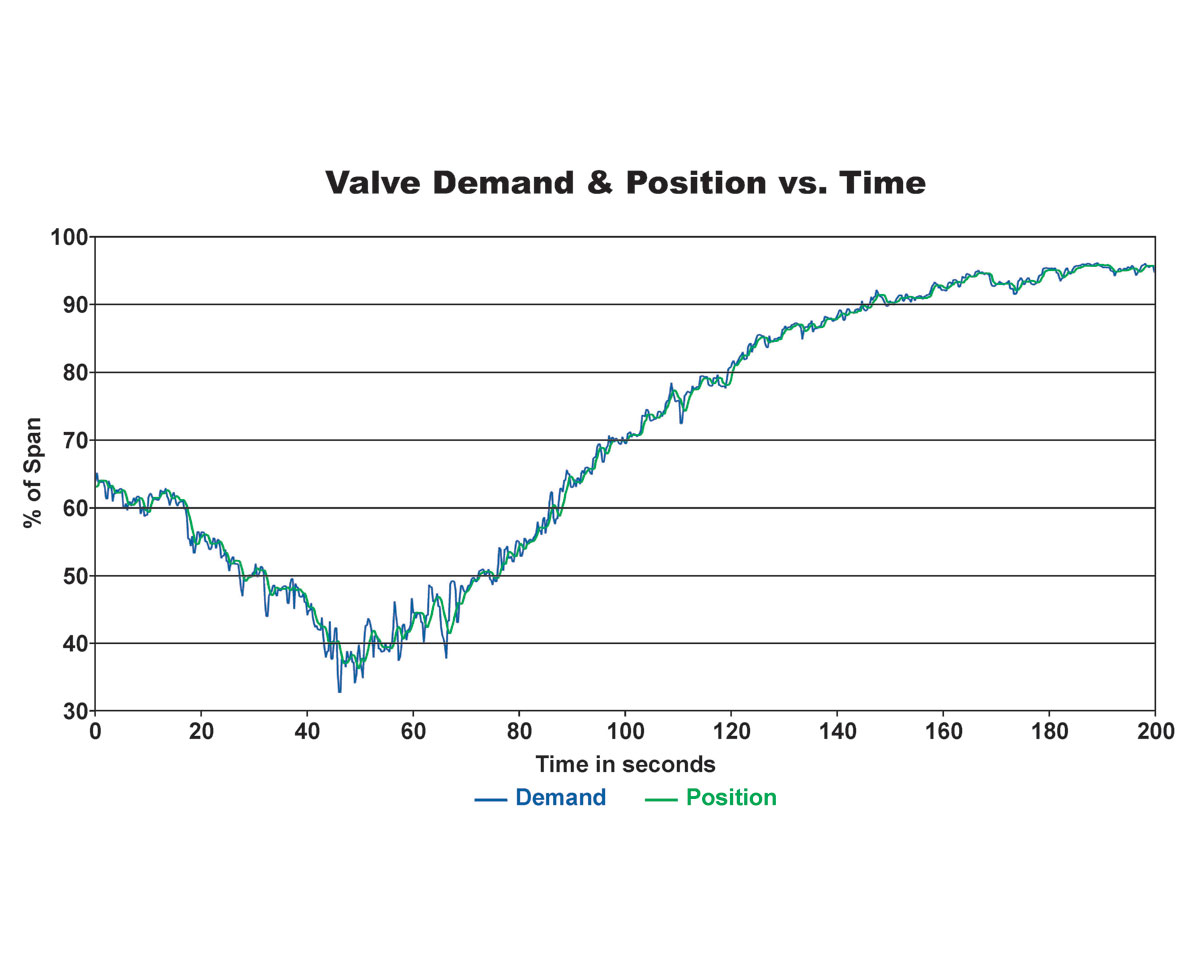

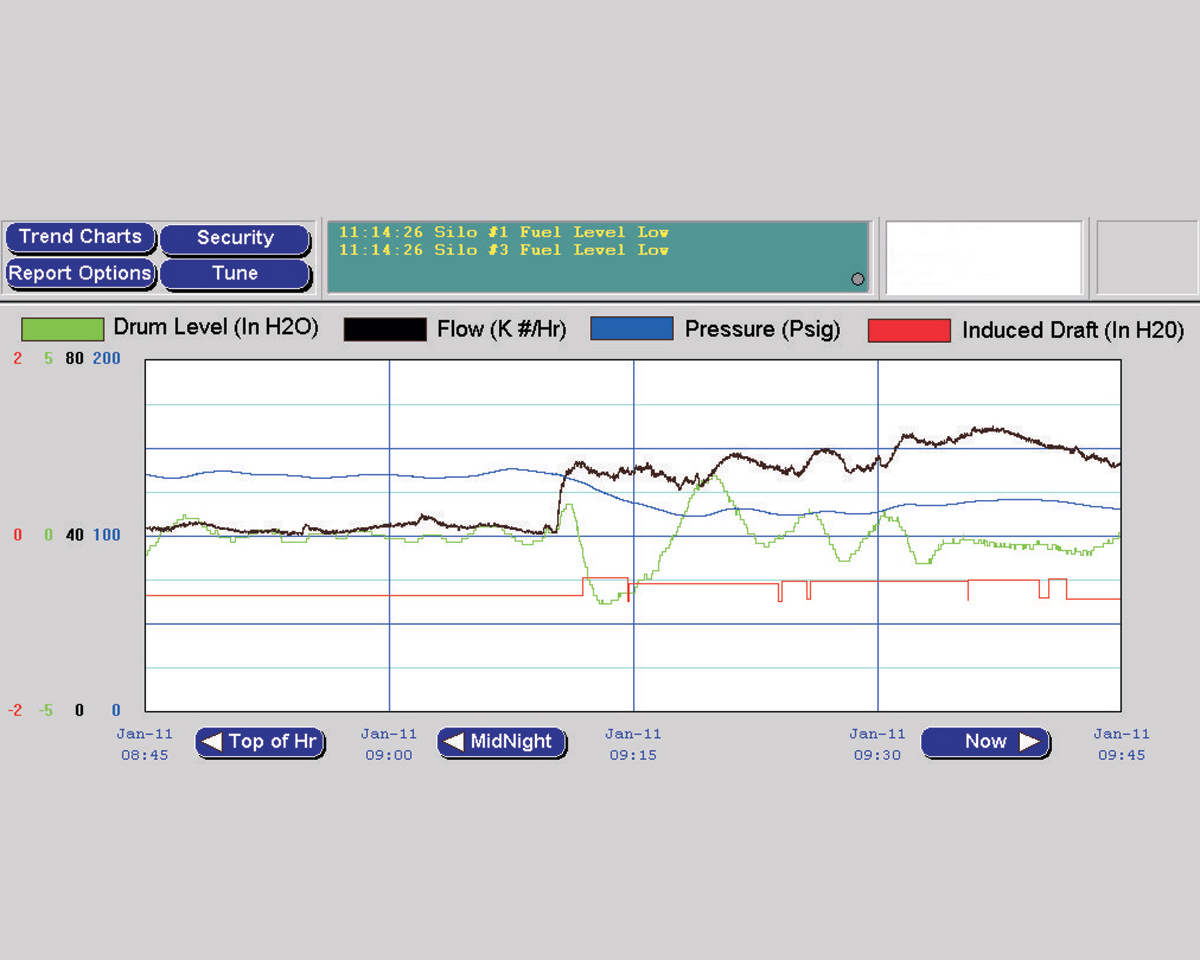

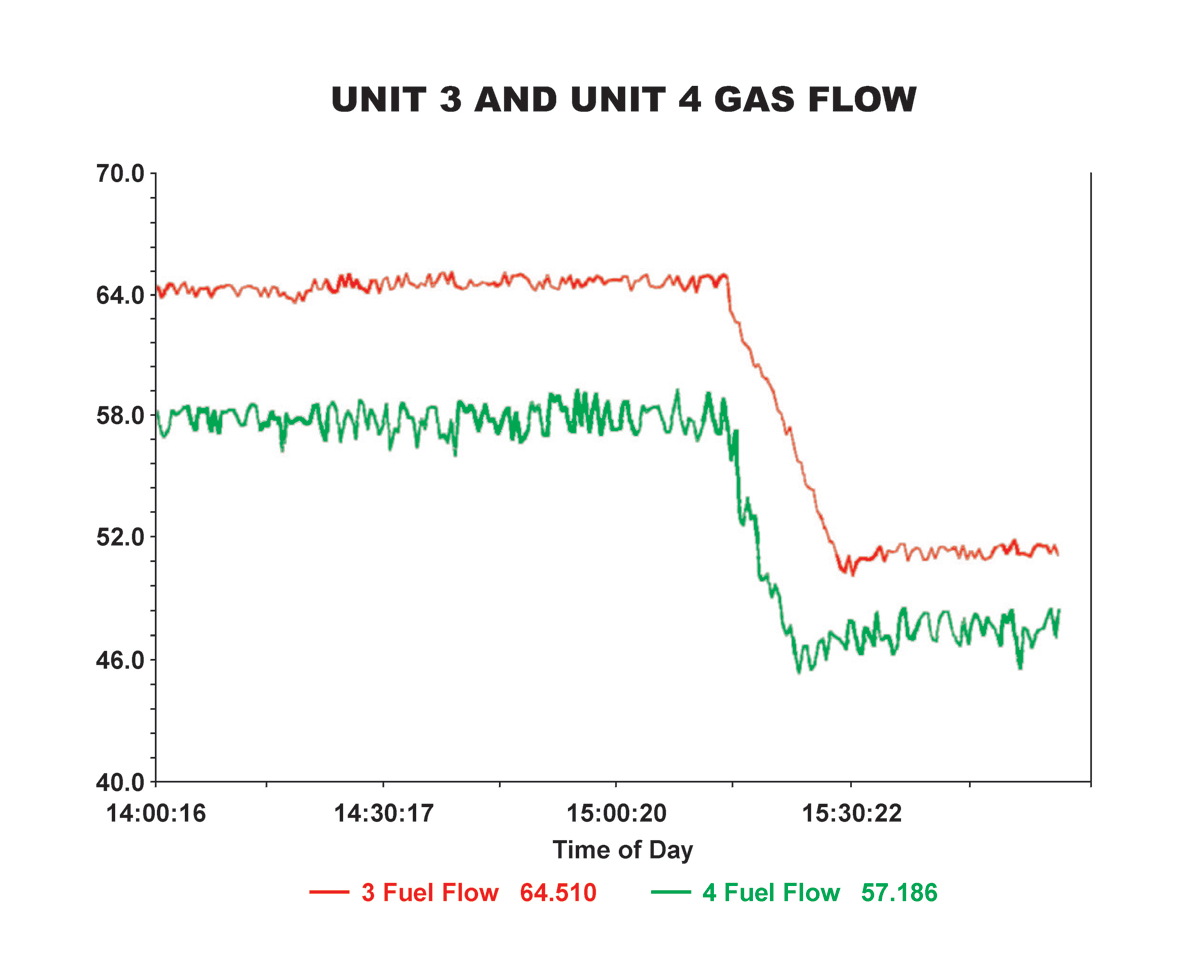

Utilities are continually investing in Beck actuators and realizing the long term benefit. Below are a series of data charts that were generated by one such Beck actuator user. Click on each in succession to enlarge the graphs.

Increasing Environmental And Economic Pressures Necessitate Control Improvements

Today’s utility industry is characterized by ever increasing emission regulations, rising fuel costs, and a growing need to be competitive. Optimizing and maintaining control performance and minimizing downtime are critical to meeting these challenges. In response, power producers are continually investing in control systems and instrumentation to meet regulations, reduce costs, and avoid costly trips and outages. In addition, as new capacity is built, these plants will also require state-of-the-art control and high levels of reliability.

Boilers Are Benefiting From Beck Drives … And The Number Is Growing

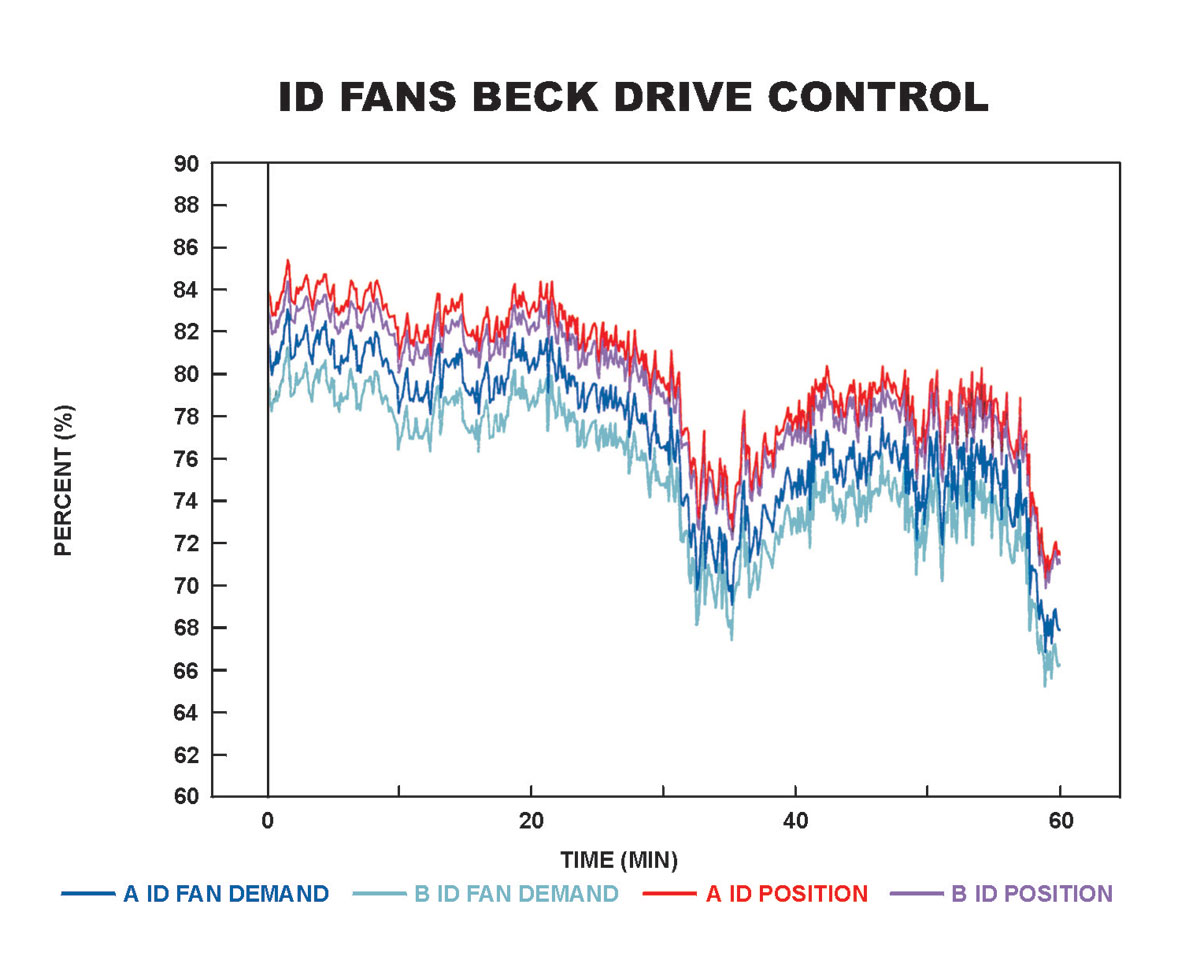

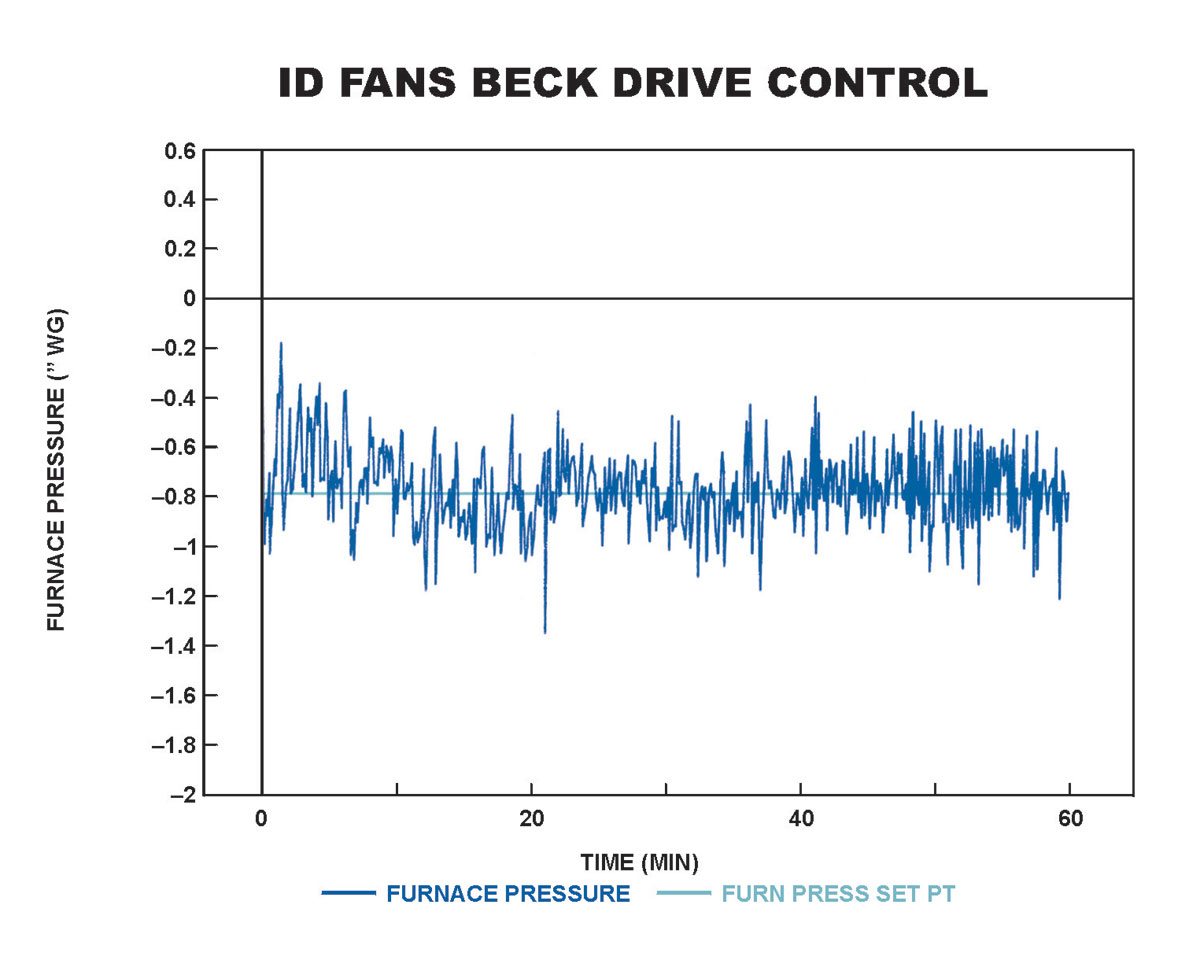

Investments in advanced control instrumentation and logic are very necessary, as is the addition of new plant systems (e.g., Overfire Air and SOFA), which are required to better control combustion emissions. However, the investments are only as effective as the precision, reliability and responsiveness of the dampers and valves. Many utilities understand this, and replace pneumatic actuators and typical electric actuators with Beck Electronic Control Drives. In fact, Beck actuators are modulating the dampers and valves of over 1,000 electric utility boilers. In addition, Beck actuators are also installed in modulating applications on over 600 industrial boilers of all sizes and styles.

Damper And Valve Actuation Is Key To Improved Boiler Control And Efficiency

In spite of the critical role of boiler control dampers and valves with respect to efficiency, safety and reliability, their performance is often ignored. In many cases, actuator problems tend to be addressed only after a serious or complete failure occurs. The rest of the time, poor performance goes undetected, or the impact it has on control is underestimated.

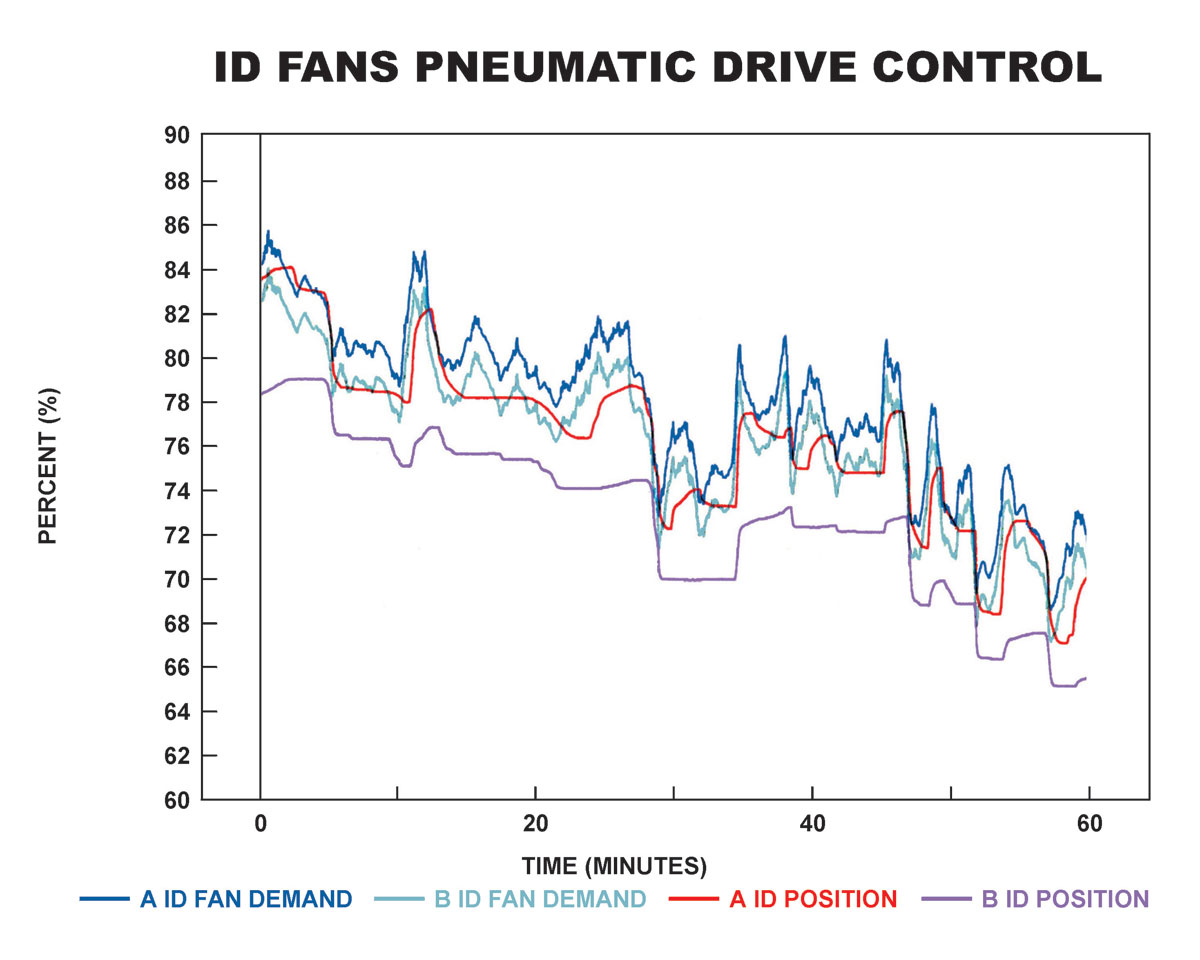

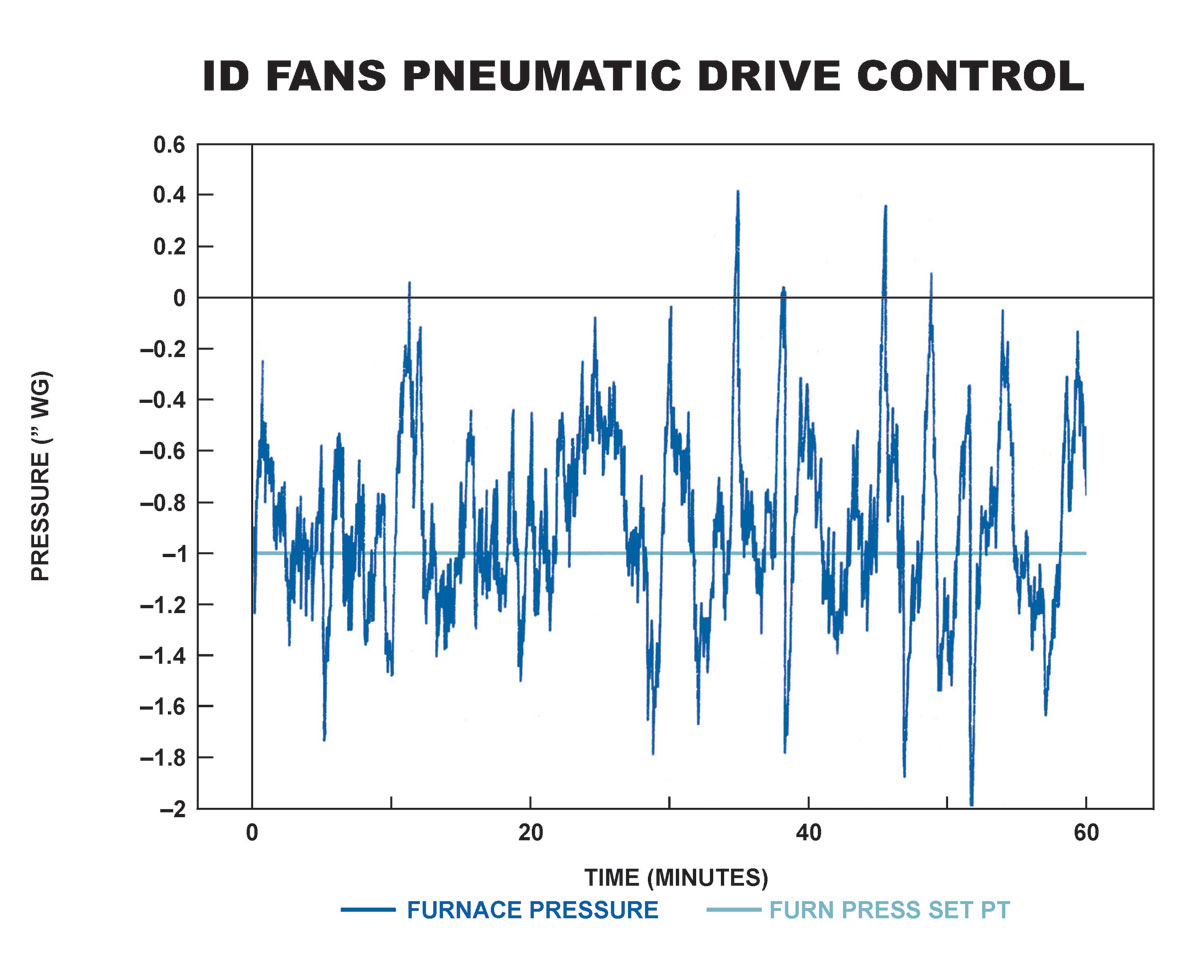

Poor damper and valve performance is a leading source of combustion control problems, often limiting ramp rate, contributing to boiler emission problems, or impacting heat rate. Pneumatic actuators are highly susceptible to stick / slip response, excessive dead time, inconsistent performance with changing conditions, and performance degradation over time. As a result, pneumatic actuation simply cannot provide the level of control performance provided by Beck actuators; nor can it provide the benefits of consistent and reliable performance over time and in harsh conditions. Similarly, typical electric actuators are poorly suited for active boiler control, since most are limited by motor duty cycles, provide less accurate positioning capabilities, and are less reliable–especially in the harsh operating conditions for which Beck actuators are designed.

Feedwater And Fuel Gas Valves

3In addition to damper control, good boiler control also requires stable feedwater and fuel control. Figures 3A & 3B below show the results of installing a Beck actuator on a feedwater flow control valve. This particular boiler is subject to extremely large and sudden steam load swings, often in excess of 30% of the boiler rating in less than one minute. With the original pneumatic actuator installed on the feedwater valve, drum level control limited the boiler’s ability to meet the steam load requirements. The installation of a Beck actuator provided the feedwater valve performance necessary for responsive, stable drum level control–even during the most severe load changes. Improving the ability to control the fuel gas flow more closely and with greater stability is an important advantage offered by the Beck actuator. Not only is boiler efficiency improved by the direct benefit of better gas flow control, but better overall boiler performance can be achieved by reducing the interactions with other control loops. (Figure 4)

Beck Drives Improve Control And Eliminate Typical Actuator Problems

Why do Beck actuators improve control and eliminate the inherent problems of pneumatic actuators and typical electric actuators?

- Beck actuators respond to a modulating controller demand signal instantaneously, regardless of changing loads and conditions. Therefore, Beck actuators will not stick or slip like pneumatic actuators, thus eliminating dead time and position overshoot.

- Beck actuators track the controller demand signal closely under closed-loop conditions, with resolution unmatched by pneumatic and typical electric actuators, ensuring responsive, tight, and stable process control.

- Beck actuators provide consistent control over time with virtually no maintenance requirements.

- Beck actuators eliminate the dependence on costly and unreliable air systems, thus eliminating problems like freezing and contamination.

- Weather, dust, dirt, and temperature (-40 to 185° F.) conditions do not affect performance.

- The extreme ruggedness and quality of Beck actuators simply means that they will outlast and outperform other actuators, thus minimizing unit trips and downtime.